The invisible beauty of a watch movement

Each manufacturer has its own way of decorating the components of its timepieces. Some watchmakers go to great lengths to decorate parts that only those who assemble the movement can see. Visit to the decoration workshops of the F.P.Journe factory during the circular-graining of the plate of the Astronomic Souveraine. Isabelle Cerboneschi

« “And beauty? It exists, without its necessity appearing obvious at first glance. It is there, omnipresent, insistent, penetrating, while giving the impression of being superfluous, that is its mystery, the greatest mystery.»

François Cheng, Five Meditations on Beauty

I wanted to start this article with this quote from François Cheng, taken from the Five Meditations on Beauty, because that’s what I thought of when I visited the decoration workshop of the F.P.Journe factory.

As I met the head of the workshop, watched her freehand polish the plate of an Astronomic Souveraine, and observed another « angleuse » polishing a screw until it was like a mirror, hence the name « mirror-like polish » , « specular polish » or “black polish”, I wondered if the owners of this collector’s timepiece would know that all of its elements have passed through the magical hands of specialised craftsmen or craftswomen who have been able to give them an extra touch of beauty.

On the day of my visit, there are five polishers in the workshop: four women and one man. The latter was trained in the world of watchmaking, as was one of his colleagues. The other three « angleurs » come from different backgrounds: respectively from watch and jewellery sales, drawing and nail art. « It’s not a job you learn at school,” explains the workshop manager. « Originally, watchmakers decorated their own movements. The demand today is not great enough to set up a training course, a network, schools, in order to nurture this trade. It is passed on from master to pupil. Within the different companies where we work, we learn recipes, which we mix together or improve. It’s a sharing of experiences. »

At the F.P.Journe manufacture, all the parts to which manual value must be added and which will then be assembled by a watchmaker, pass through the hands of the angleurs. They are all masters of circular-graining, chamfering, drawing and black polishing, techniques that are all hand made at F.P.Journe.

A polisher is in the process of making a black polish. Historically, watchmakers used this technique to prevent corrosion: the more polished a surface is, the less likely it is to be attacked by rust. It is also a game with light: the surface of the piece is smoothed until the reflection that passes through it becomes black. « The piece to be polished is placed on a mould, which itself is placed on a tripod to create stability,” explains the workshop manager. « Then the piece is rubbed on a zinc support – a softer material than the one to be polished – on which a white paste is spread, a mixture of 0.2 micron diamond powder that is mixed with an oil. Some houses use sweet almond oil, we use car engine oil. Everyone has their own recipe. The best texture is when it looks like pancake dough and makes threads. I learned to make it like that. But you can always adjust it: if, for example, the polish turns blue, it means that the dough is too full of oil and that you need to add diamond powder. And stretch marks appear when the paste is too full of powder. It must therefore be liquefied. To achieve a black polish on small surfaces you can also use gentian wood, whose pith is very soft. And it doesn’t matter whether the piece is visible or not: the aim is perfection. That is the beauty of fine watchmaking. »

The angleur’s job is by no means a series of repetitive acts. The slightest variation in emotion, in mood, can be seen in a piece: it is a skill that calls on the feelings of the person. It requires a high level of self-discipline.

Circular graining, like all hand-made decoration techniques, gives the timepiece its uniqueness, because the same gesture can never be reproduced twice. Some houses like a tighter beading, others a wider one. « I use a medium spacing and rubbers with a diameter of 1 to 3 mm”, explains the manager.

The day of the visit was a lucky day: the latter was circular-graining the plate of an Astronomic Souveraine. A rare moment. To begin with, she clamps it on a fixture that she places on a mobile plate and she evenly applies a rotating eraser attached to the end of a mandrel. This creates small circles on the material and, by overlaying them, she obtains a pretty spiral that reflects the light, like a mini-kinetic work. The result depends on the rhythm she uses to rotate the piece and press the little eraser on it. « It’s a dance,” she says. « It takes a certain coordination between our eye and our gesture and that’s what sets the tempo. You don’t achieve the regularity of a machine but the aim is to make something regular. There can be small variations: this is what will define the hand circular-graining from the machine one and what will give its charm to each watch which will be unique ». To complete the circular-graining of a plate, it will take her 45 minutes.

The result is impressive, but the most difficult technique to master is hand chamfering which requires a certain dexterity to be able to perfectly use the file, the knife, the polishing iron, the cabrons, the gentian wood and all the other tools that are often made by the craftsman or craftswoman. « Hand bevelling calls on our finishing skills,” explains the workshop manager. « It requires finesse, delicacy and precision. We take a piece, cover it with polishing paste and then rub it with an iron until we obtain a mirror-like polish on the corner. The polishing iron must be made of soft iron. I make my own with old umbrella ribs I found at a flea market. »

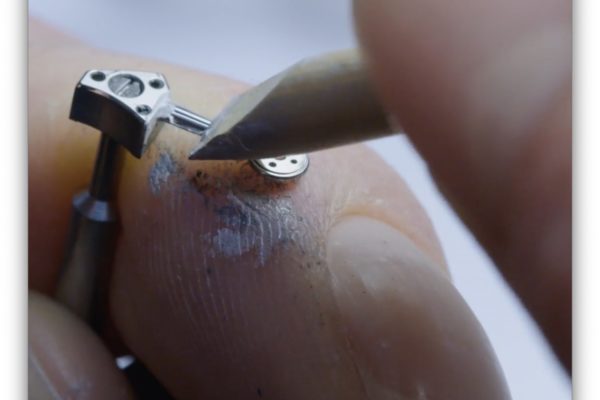

The last technique to be discovered on this day is the bevelling with a piercer used to rework bridges. This is a completely different technique: the polisher approaches the piece with wheels made of cardboard, leather or wood, which turn on an axis. They have been cut beforehand, depending on the shape of the workpiece to be bevelled. “Learning how to use the piercer takes much longer because you have to know how to choose your wheels, cut them yourself, and choose a speed of rotation according to the material used and the shape of the part », explains the polisher.

Once the timepiece is assembled, all the cleverly decorated elements become partially undetectable. They become the beautiful secret of the watchmaker, the workshops and the owner of the timepiece. Decoration is an art of humility and self-control. And when one observes the angleurs at work, one understands that their quest is for an invisible beauty.